Training as Represented by a Circle

NOTE: This post is from one of our frequent contributors to this blog, "Birdseye59604."

|

| Norwegian Cookie Cake |

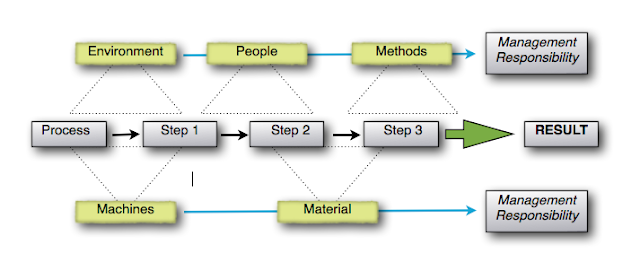

When a new person is starting in a job the Enterprise has an indoctrination training planned even if one does not exactly know a new employee’s competence level. Based on historical facts, one assumes that a new person is qualified to enter the Circle of Training at the position’s Level of Performance Criteria.

When there are Management changes an Enterprise is conducting a “for cause” Management Review and a review of change which could affect the established Safety Management System. Should there be a change of Accountable Executive, it’s the top ring of the “Circle Cookie Cake” where training is applied. When there is a change of an established operational process, it is one of the lower rings where training is applied. Training applies to each circle of Performance Criteria.

Each circle represents an Enterprise’s planned training for Competence, Effectiveness and Continuous Improvement.

When a person has completed the circle’s indoctrination training level of training, it becomes a simple task to add SMS&QA training; technical; recurrent; and training for Continuous Improvement.

Your thoughts.....

BirdsEye59604

|

| Continuous improvement circle analogy is natural |

Each circle represents an Enterprise’s planned training for Competence, Effectiveness and Continuous Improvement.

Your thoughts.....