Quality Assurance Program

By OffRoadPilots

A successful quality assurance program is the result of an effective quality control

system. The purpose of a quality assurance program is to establish confidence or

certainty in abilities to maintain regulatory compliance and safety in operations.

When operating with a healthy quality assurance program, there should not be any

unknown findings associated with audits or inspections. Without a quality control

system in place, quality assurance, or certainty of operational control, is achieved

by random chance only.

Assurance is the process of

analyzing and using it to

assess operational processes

and records. Assurance is

verifying is records and

reports are as per SMS

principles. Assurance also

confirms whether the SMS

records are accurate.

Assurance is the task of

assessing processes,

operations, services, and

reliability. The main aim of

assurance is to check the accuracy of reports. It also assures the accountable executive, tenants, airport users, and stakeholders that there is no misrepresentation done in records, no misuse of funds, no fraud, and no fraudulent activities done in a company or done by the company. Assurance is applied to assess the process, the procedure, and operations, and these processes, procedures, and systems are observed closely to ensure the process is right and gives optimum results. Assurance specializes in assessing and improving the quality of the information in a company. Assurance is a tool that helps in the decision- making process as it works on customer feedback, airport and airline personnel

feedback, feedback from the general public, or other areas where information is

required in organizational decision-making.

Quality assurance is about overseeing SMS processes as well as the final task to

ensure that operators are in compliance with regulatory requirements, standards

and their SMS policy. Quality assurance firstly requires operators to implement

their quality management system (QMS) and then involve audits or periodic

inspections of the system. Quality assurance hence means ensuring whether the

QMS is operating as expected i.e., helping to govern processes and output. With

quality assurance methods, operators generate key insights of their processes and

identify any nonconformity. When operating with a daily quality control system,

findings are discovered prior to audit and inspections. There are no good reasons

for audit findings.

Safety management is

different than safety

assurance since it is about risk

exposure or vulnerabilities in

airport or airline operations.

Risks are hazards defined by

exposure, likelihood and

severity that can affect

operations both tangibly and

intangibly such as workplace injuries, defective products, fire, loss in revenues,

market volatility, and negative publicity. Safety assurance is about internal and external exposures to identify the areas that are exposed to hazards. Safety

assurance methods include performing risk assessments, risk analysis, system

analysis, root cause analysis, corrective actions, or preventive actions.

Over a period of three years, all regulatory non-compliance findings for airports

were of their obligations as airport operators, and of their quality assurance

programs. Regulatory non-compliance findings were given to small, medium, and

large international airports. There are no good reasons for airports, or airlines, to work with processes that generates findings. It is just as simple and easy to do things right as it is to do it the wrong way.

A quality assurance program

is a component and integral

part of a safety management

system (SMS), and is

managed by the SMS

manager, in the same

manner as the other

components of an SMS is

managed by the SMS

manager. A safety

management system must

include a safety policy, a

goalsetting process and to

measure the attainment of

their goals, hazard

identification process and

manage associated risks, training processes, reporting processes, a quality

assurance program, review and audit processes, and any other requirements

prescribed by the regulations. Without a quality assurance program, an SMS is

incomplete since there is a lack of quality control. A safety management system is

a businesslike approach to safety. In a successful business, cashflow quality control

is achieved by cash register entries. Quality assurance of a business is to conduct

review and audits to learn about cash register reliability, and compliance with

regulatory accounting principles. Quality assurance of a safety management

system is to conduct review and audits to learn about data entry reliability and

learn to what level their processes conform to regulatory requirements. An

example of compliance level could be a safety policy that the accountable

executive has approved but not communicated to all personnel.

The quality assurance

program includes a process

for quality assurance that

includes periodic audits of

activities and audits, for

cause of those activities. The

certificate holder (CH) is

responsible for records

relating to the findings

resulting from the quality

assurance program are

distributed to appropriate

manager for corrective

action and follow-up. It is

important to note that

corrective actions from

audits and follow-up are

assigned to operational managers, and not to the SMS manager. A complete audit

is due within 12 months after a certificate is issued, and audits of the entire quality

assurance program carried out every three years, calculated from the initial audit.

Conventional wisdom is that an audit of the entire quality assurance program

(QAP) is an audit of the audit itself. When the regulations call for an audit of the

entire quality assurance program, they are calling for an audit of the airport’s

quality assurance program, which is how airport personnel do their work to ensure

quality delivery of services. Quality assurance includes the prerequisite of a daily

quality control system. An audit of the entire QAP is therefore an audit of

regulatory compliance, standard compliance, SMS policy compliance, process

compliance, and safety in operations compliance within all areas of airport

operations and their third-party contractors. In other words, the quality assurance

program to be audited is quality assurance of how the work is done day in and day

out, as opposed to how work is expected to be done. If a quality assurance

program is implemented to find faults based on arbitrary expectations, then the

Without control, quality cannot be measured.quality assurance of actual work done is eliminated. A quality assurance program is not separated from operations but is the operations itself. On the other hand, an audit conducted by an external auditor is designed to find faults based on expectations, since a third-party, or external auditor only knows the expectations

and does not know random work practices.

A quality assurance program

requires audit checklists to

be used. A simplified audit

checklist has three options,

which are Yes, No, or N/A,

and a field for comments.

Airport audits are of all

activities controlled by an

airport operations manual

(AOM). Areas controlled of

an AOM are the standards

to be met and the services

to be provided by an airport operator. Standards to be met are airport standards

compliance for issuance, and maintenance of the airport certificate. Services to be

met are services by the airport operator to maintain regulatory compliance, and

additional services required for airport operations, such as aircraft parking, fuel

service, apron for boarding and deplaning passengers and other services required

for an airport to provide customer service.

There are no requirements for a certificate holder to appoint a quality assurance

manager. However, several SMS enterprises are assigning the quality assurance

portfolio to a responsible manager. A safety management system is under the

control of an accountable executive. With the lines of authority established, the

certificate holder has a tool to navigate their quality assurance program. An AE is

responsible for meeting the requirements of the regulations, while the liability

rests with the certificate holder.

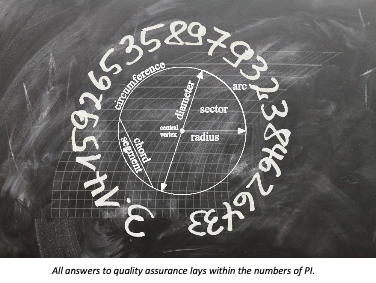

All answers to quality assurance lays within the numbers of PI.An operational daily quality control system is applied for successful navigation of

the quality assurance program. The quality control system is a daily rundown of

tasks and activities, and where these activities are linked to regulatory

requirements, standard requirements, or SMS policy statements.

Operating with a quality assurance program is a simple task since it does not

change any of the work practices or processes. The quality assurance program

required includes a process for quality assurance that includes periodic reviews or

audits of the activities authorized under a certificate and reviews or audits, for

cause, of those activities. For a quality assurance to be effective it is monitoring

operations to review patterns and for tasks and activities to remain within their

assigned paths. A daily rundown within a quality assurance program assigns

multiple regulatory links to one task. One example is the daily inspection at

airports. Not only are several of the obligations of an airport operator taken care

of, but any findings during the inspection are automatically populated into a

hazard register. By applying this principle, a finding, which normally is negative to

operations, is turned around to a positive event by adding it to the hazard register

and comply with an SMS requirement. SMS is not about the negatives, but about

the positive, and discover why things goes right and to discover positive events

from findings. Conducting change management, safety cases, and system analyses

are all components of a healthy quality assurance program. By conducting these

tasks an SMS enterprise comply with their regulatory SMS requirement to operate

with a safety management system that includes a quality assurance program. As

their daily rundown system is populated with tasks, activates and work practices,

they establish their tailored quality assurance system.

A successful quality assurance program happily welcomes the required triennial

audits since a daily quality control system maintain regulatory compliance and

safety in operations.

OffRoadPilots

No comments:

Post a Comment